Kawasaki Breaks Ground on World’s First Centrifugal Hydrogen Compressor for Liquefaction Plants

Kawasaki Heavy Industries, Ltd. has begun construction of a groundbreaking demonstration facility for the KM

Hydrogen can be stored in many ways, depending on the application and the desired characteristics of the storage system. Some common ways of storing hydrogen include:

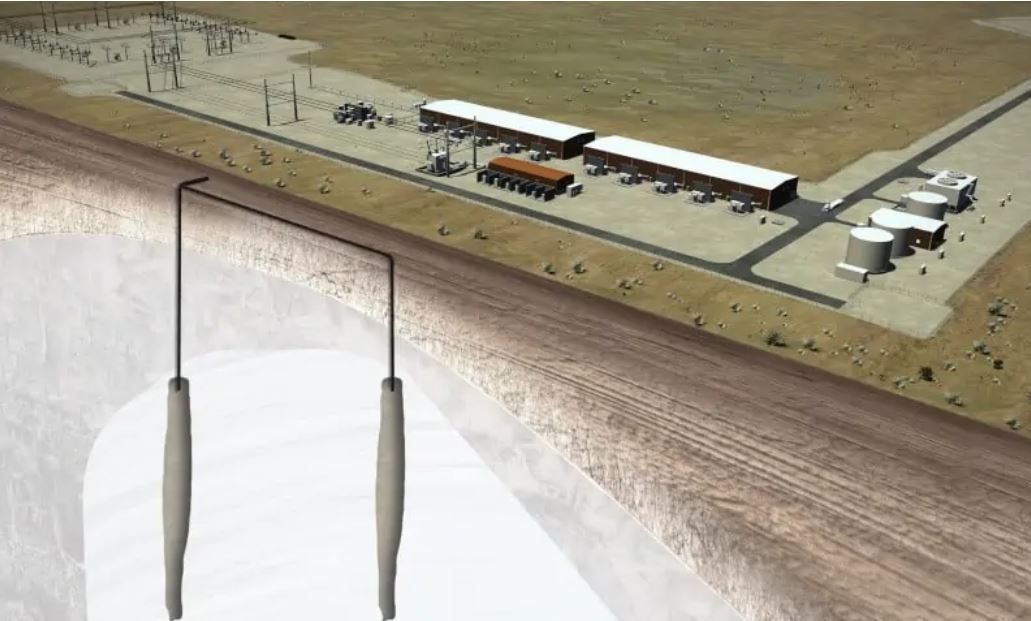

Geological hydrogen storage refers to the practice of storing hydrogen underground, in geologic formations such as depleted oil and gas reservoirs, salt caverns and unmineable coal seams. This method of hydrogen storage has several advantages, including the ability to store large amounts of hydrogen safely and securely, as well as the potential to use existing infrastructure, such as pipelines, for transportation. However, geological hydrogen storage also has its challenges, including the need for thorough characterization of the storage site and the potential for leakage of hydrogen into the atmosphere.

2. Compressed hydrogen: Hydrogen can be stored in high-pressure tanks or cylinders, where it is compressed to a pressure of up to 10,000 pounds per square inch (psi). This is a common method of storing hydrogen as it allows for a high energy density and easy transportation. This makes it well-suited for applications where space is limited, such as in vehicles. Compressed hydrogen is also relatively safe to handle and transport provided that the tanks are well-designed and maintained. One of the disadvantages of compressed hydrogen is that it requires a relatively high pressure to store the gas, which can be expensive and potentially dangerous. The tanks must be designed to withstand high pressure, and if they fail, the hydrogen can be released rapidly, potentially leading to an explosion. Additionally, the process of compressing hydrogen requires energy, which can reduce the overall efficiency of using hydrogen as a fuel. Overall, compressed hydrogen is a commonly used method of storing hydrogen for use as fuel. It has several advantages, such as high storage density and relative safety, but it also has some disadvantages, such as the need for high-pressure storage and the associated costs and risks.

3. Liquid hydrogen:

Hydrogen can also be stored in liquid form, by cooling it to a temperature of -253°C (-423°F). This requires specialized equipment and insulation to maintain the low temperature, but it allows for a high energy density and easy handling. Liquid hydrogen is commonly used for long-term storage or for applications that require a large amount of hydrogen, such as rocket fuel. One of the main advantages of storing hydrogen in liquid form is that it allows for a high energy density. Liquid hydrogen has a much higher energy density than gaseous hydrogen at normal temperatures, so it can be stored in a smaller volume. This makes it well-suited for applications where space is limited, such as in vehicles or portable fuel cells. Another advantage of liquid hydrogen is that it is relatively easy to handle and transport. Unlike compressed hydrogen, which requires high-pressure tanks, liquid hydrogen can be stored in tanks that are not under high pressure. This makes it safer to handle and transport, and reduces the risk of explosions.

One of the main disadvantages of liquid hydrogen is that it requires specialized equipment and insulation to maintain a low temperature. This can be expensive and can reduce the overall efficiency of using hydrogen as a fuel. Additionally, liquid hydrogen is highly flammable, and if it leaks it can create a risk of fire or explosion. Overall, liquid hydrogen is a useful method of storing hydrogen for use as fuel. It has several advantages, such as high energy density and ease of handling, but it also has some disadvantages, such as the need for specialized equipment and the associated costs and risks.

4. Material Based Hydrogen Storage

Hydrogen-storage materials: Hydrogen can also be stored in solid materials, such as metal hydrides, palladium, metal-organic framework or carbon nanotubes, where it is adsorbed or absorbed by the material. This method allows for a high storage density and low pressure, but it can be slow to release the hydrogen and may require specialized equipment. Hydrogen-storage materials are commonly used for portable or stationary applications, where a high energy density and low weight are desired.

5. Hydrogen storage in Ammonia

Ammonia can be used as a hydrogen storage medium. In this process, hydrogen gas is combined with nitrogen gas to produce ammonia (NH3), which can be easily stored and transported. When ammonia is needed, it can be converted back into hydrogen and nitrogen through a process called steam reforming. This process is widely used in the chemical industry and has the potential to be used for hydrogen storage in the future. One of the advantages of using ammonia as a hydrogen storage medium is that it has a high hydrogen density by weight, allowing for a relatively compact and lightweight storage system. However, it does require careful handling, as ammonia is toxic and can be explosive under certain conditions.

Overall, the choice of storage method depends on the specific application and the requirements of the hydrogen system.