Kawasaki Breaks Ground on World’s First Centrifugal Hydrogen Compressor for Liquefaction Plants

Kawasaki Heavy Industries, Ltd. has begun construction of a groundbreaking demonstration facility for the KM

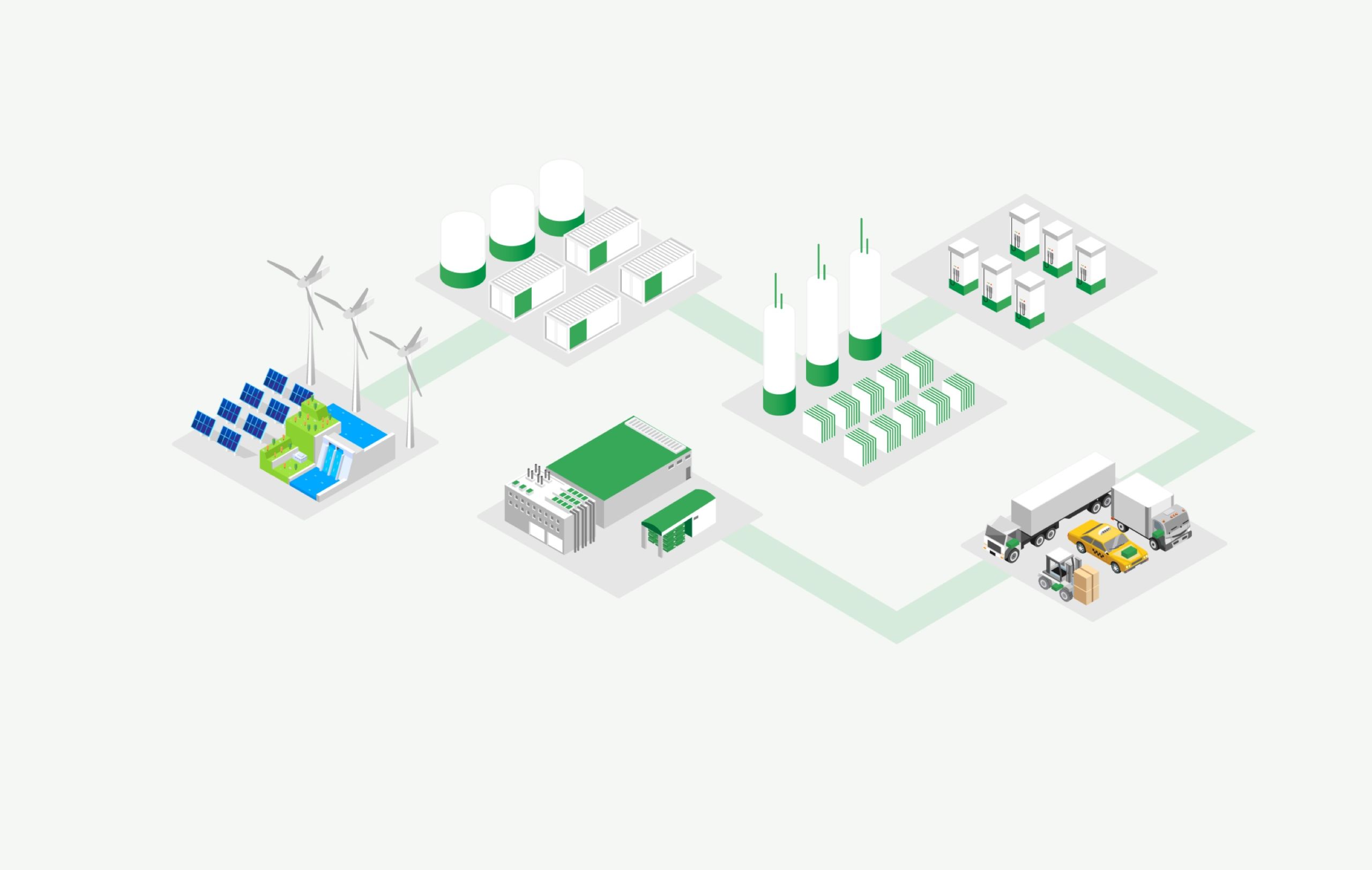

A Proton Exchange Membrane (PEM) electrolyzer is an advanced and highly efficient electrolysis technology that plays a vital role in the production of green hydrogen, a sustainable and eco-friendly energy source. Utilizing a solid polymer electrolyte, or proton exchange membrane, the PEM electrolyzer facilitates the conversion of water into hydrogen and oxygen through a process known as electrolysis. As the world grapples with climate change and seeks alternatives to fossil fuels, the PEM electrolyzer has emerged as an essential component in the quest for sustainable energy solutions. Its unique features, such as compact design, rapid response time, and ability to efficiently produce hydrogen at high pressures, make it particularly well-suited for integration with renewable energy sources like solar and wind. As a result, the PEM electrolyzer not only helps to advance the production of green hydrogen but also contributes to the broader goal of transitioning to a low-carbon, sustainable energy future.

PEM (Proton Exchange Membrane) electrolyzers use a proton exchange membrane to separate the anode and cathode compartments of the electrolyzer cell. The membrane is typically made of a polymer, such as Nafion, and is designed to allow protons (hydrogen ions) to pass through while preventing the mixing of the electrolyte solutions on either side of the membrane.

The manufacturing process for PEM electrolyzers typically includes the following steps:

There are several leading manufacturers of PEM (Proton Exchange Membrane) electrolyzers for green hydrogen production. These include:

ITM Power, a pioneering company in the field of hydrogen technologies, has established itself as a prominent manufacturer of PEM electrolyzers, contributing significantly to the growth and adoption of green hydrogen solutions. As a trailblazer in this domain, ITM Power actively participates in the development of hydrogen fueling stations and a wide range of projects that harness the potential of green hydrogen. By leveraging their expertise in PEM electrolyzer technology, the company plays a crucial role in driving advancements in sustainable energy infrastructure, ultimately promoting a greener, more eco-friendly future. ITM Power's innovative approach and commitment to excellence have positioned them at the forefront of the hydrogen economy, where they continue to make a meaningful impact on the global energy landscape and help shape the transition towards clean, renewable energy sources.

NEL Hydrogen, a leading company in the hydrogen technology sector, specializes in the design and manufacture of PEM (Proton Exchange Membrane) electrolyzers for efficient hydrogen production. NEL's PEM electrolyzers boast a compact, user-friendly design, catering to a diverse array of applications, such as on-site hydrogen generation, hydrogen refueling stations, and hydrogen storage systems. The versatility and adaptability of NEL's electrolyzers make them an attractive choice for projects of varying scales and requirements. The capacity of NEL's PEM electrolyzers can be customized depending on the specific model and configuration, offering a broad selection of electrolyzers tailored to different hydrogen production capacities. By stacking multiple electrolyzers, NEL's solutions can accommodate increased production needs. The C series, for instance, provides hydrogen production capacities of 10, 20, and 30 Nm³/h at 0°C and 1 bar, making it well-suited for small to medium applications. For larger-scale endeavors, the M series offers higher production capacities of 1,698 Nm³/h, 2,952 Nm³/h, 3,936 Nm³/h, and 4,920 Nm³/h. Through their innovative electrolyzer technology, NEL Hydrogen continues to advance the adoption of green hydrogen and contribute to a more sustainable energy future.

Cummins, a global leader in power generation solutions, has expanded its portfolio to include hydrogen technologies, such as PEM (Proton Exchange Membrane) electrolyzers. These electrolyzers are a crucial component in the production of green hydrogen, a clean and sustainable energy source with potential applications across various industries.

Cummins' PEM electrolyzers leverage their advanced engineering capabilities to offer efficient, reliable, and scalable hydrogen production solutions. By focusing on high-performance and innovative designs, Cummins aims to contribute significantly to the growing hydrogen economy and help accelerate the transition to more sustainable energy sources.

With their expertise in power systems and commitment to clean energy, Cummins is well-positioned to play a key role in the hydrogen industry by providing cutting-edge PEM electrolyzers and supporting the widespread adoption of green hydrogen for a more sustainable future.

Plug Power, a prominent player in the clean energy industry, specializes in the development and manufacturing of PEM (Proton Exchange Membrane) electrolyzers, which are essential in the production of green hydrogen. These electrolyzers generate hydrogen through the process of electrolysis, converting water into hydrogen and oxygen using electrical energy, ideally from renewable sources.

Plug Power's PEM electrolyzers feature advanced engineering, high efficiency, and reliable performance, making them suitable for various applications, such as hydrogen production for fuel cell vehicles, grid balancing, and industrial uses. By offering scalable and modular solutions, Plug Power enables businesses and organizations to integrate green hydrogen into their energy systems seamlessly.

As a key innovator in the hydrogen and fuel cell industry, Plug Power's commitment to clean energy and sustainable solutions is evident in their continued focus on advancing PEM electrolyzer technology. Their products and services contribute to the growth of the hydrogen economy and help facilitate the transition to renewable energy sources for a more sustainable future.

Siemens, a global powerhouse in the fields of industry, energy, and technology, has ventured into the development and manufacturing of PEM (Proton Exchange Membrane) electrolyzers, which are vital in the production of green hydrogen. These state-of-the-art electrolyzers utilize a solid polymer electrolyte to facilitate the electrolysis process, converting water into hydrogen and oxygen using electrical energy from renewable sources.

Siemens' PEM electrolyzers are designed with cutting-edge features, such as high efficiency, rapid response time, and the ability to operate at high pressures, making them ideal for a variety of applications, including grid balancing, hydrogen refueling stations, and industrial processes. The Silyzer product series, offered by Siemens, is a testament to their dedication to providing advanced hydrogen solutions. The Silyzer 200, for example, has an electrical capacity of up to 2 MW and a hydrogen production rate of approximately 335 Nm³/h, while the larger Silyzer 300 series can provide a capacity of 6 MW and produce around 1,000 Nm³/h of hydrogen.

These innovative electrolyzers are designed to be scalable and modular, allowing for easy integration with renewable energy sources and ensuring seamless adaptability to various hydrogen production needs. Through their commitment to developing efficient and reliable PEM electrolyzers, Siemens plays a crucial role in the global transition to sustainable energy solutions and contributes to the advancement of the hydrogen economy.

These are just a few examples of the leading manufacturers of PEM electrolyzers for green hydrogen production, there are more companies involved in the market. It's important to note that the selection of a particular electrolyzer depends on specific application and the requirement of the project.